ECOFLOW advanced, conventional pump monitoring system

A virtual flowmeter, ECOFLOW utilises advanced machine learning and takes conventional pump monitoring to a new level. It is your essential tool for real-time performance tracking in small to medium sized stations or where thermodynamic approach is not suitable.

Why use conventional pump monitoring?

The conventional methodology is suitable in wastewater or low head applications where thermodynamic technology is not well suited.

Often hidden characteristics are discovered that can lead to major improvements in overall operating efficiency and pump lifecycle costs. Results can provide valuable pump data that will minimise whole-life costs through real-time optimisation of parallel pump operation and deliver accurate pump efficiency and performance data for planning capital expenditure.

Pump monitoring can also provide information that can be used to reduce energy consumption, carbon emissions, hydraulic failure and premature wear.

How ECOFLOW works

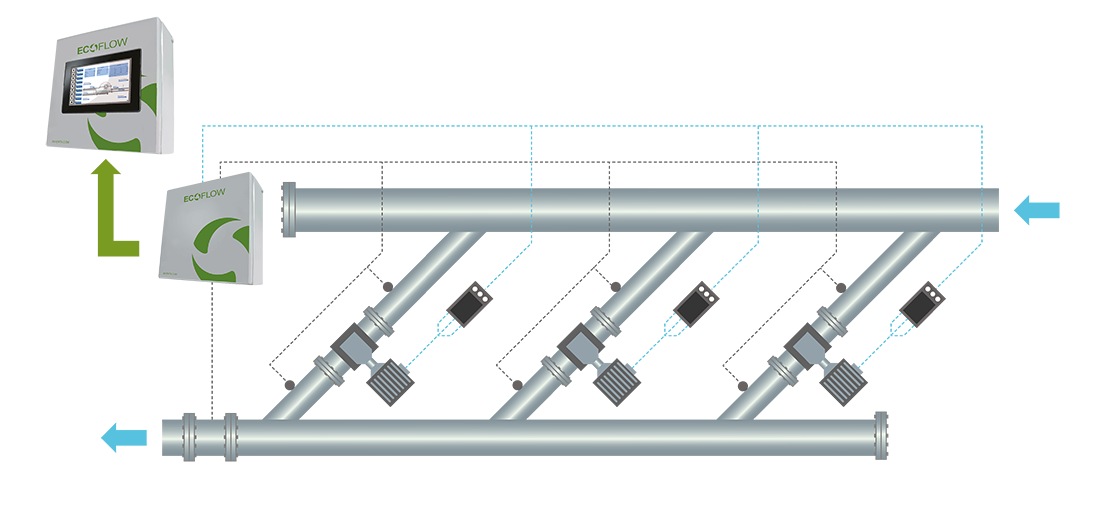

ECOFLOW technology utilises your existing system flowmeter along with Pressure and power measurement from each pump to create a virtual flowmeter on each pump. This makes it possible to measure individual flow rate and efficiency for each pump mainly from existing site measurements.

Above is a schematic showing how our ECOFLOW system connects to a pumping system and the flow of data being gathered.

COMMONLY MONITORED APPLICATIONS

For small to medium-sized pumps

This technology utilises existing site instrumentation to deliver the most cost effective monitoring of small machines

newfaqitem

SYSTEM COMPONENTS

One ECOFLOW pump station monitor

One 10-bar suction pressure transducer

One 20-bar delivery pressure transducer

One power measurement system (LV/HV)

One touch screen local operator panel

One pump-side data acquisition unit

Two insertion glands per pump

Operator interface software

Alongside system components, our ECOFLOW pump monitoring system captures, processes and provide data to managers and operators via our HydraNet software. Alternatively the same data can be integrated with existing SCADA systems.

Every minute of the day and night, enhanced information is made available from ECOFLOW to improve station efficiency and reduce operating costs.

SYSTEM HIGHLIGHTS

Requires no user maintenance

Works with virtually any pump (including low head systems where thermodynamics is less effective)

Measures individual pump efficiency and flow rate using our innovative and patented core technology

Trends pump degradation over time, predicting a cost-effective time for replacement, refurbishment, coating or maintenance

Supports planned maintenance programmes by tracking reduction in pump efficiency

Provides pump head, flow, efficiency and power

Integrates with SCADA, standalone or web-access (security assured)

Offers a real alternative to regular on-site pump testing