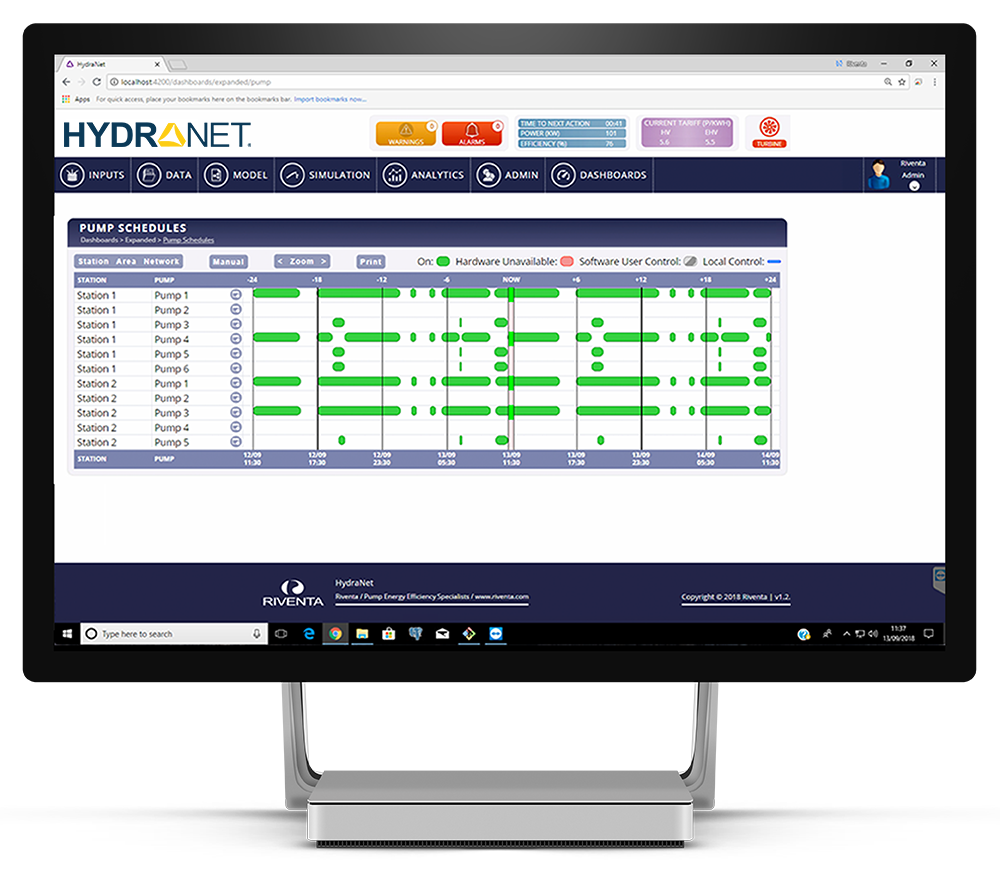

HYDRANET real-time decision support software

Cloud-based or locally hosted, HydraNet delivers real-time decision support to operators or existing automated control systems. It comes with in-built analytics and auto-reporting, features for managing OPEX and CAPEX, customisable alarms and warnings, and a GIS interface.

Why use real-time software?

HydraNet and its Optimiz Station and Optimiz Network modules deliver real-time decision support to station operators, providing 24/7 guidance on the best combination of pumps to meet demand at the least cost. This is critical where demand is variable, and variable speed drives are employed.

The software also supports planned maintenance using performance trending over time. It is capable of identifying the best time for maintenance and, by estimating refurbishment costs, it can also track efficiency shortfall, and alert when the payback meets client decision level.

To identify energy savings, you can compare ‘actual station cost performance’ for a period against the ‘least cost benchmark’. This is used to evaluate the savings attributable to a monitoring system. Plant upgrades and modifications that could reduce future energy costs can be identified too, such as pump size changes. Using our GPX Index, it is also possible to benchmark current and potential benefits from asset upgrades.

How HYDRANET works

HydraNet provides a fully customisable management dashboard, which contains dynamic live data and provides an overview of day-to-day pump performance, condition and reliability. This delivers real-time decision support to your operators or existing automated control system. So, whether you’re planning upgrades on a 25-year time frame, or minimising energy use today, HydraNet will enable you to optimise pumping operations.

COMMON APPLICATIONS

Often utilised when we undertake a major station optimisation project to inform optimisation decisions.

Common applications include: water utilities, smart city projects, decarbonisation of water distribution networks, and any other process with multiple turbo machines (including pumps, blowers and turbines).

Any process comprising of multiple systems of pumps, blowers and turbines.

In municipal water distribution, HydraNet is part of the Smart City and Digital Twin technology space.

SYSTEM COMPONENTS

Cloud-based or locally hosted

Fully customisable management dashboard

In-built analytics and auto-reporting

Features for managing OPEX and CAPEX

Customisable alarms and warnings

GIS interface

SYSTEM HIGHLIGHTS

By providing dynamic live data at your fingertips, HydraNet provides an essential overview of day-to-day pump performance, condition and reliability.

The pump schedules dashboard delivers real-time decision support to your operators or existing automated control system.

A robust optimisation engine and intuitive GUI platform enables network level decision making to be optimised and operational teams empowered to reduce risk, reduce cost and increase the level of control – particularly in water distribution where regular exceptional events need flexibility and continuity of supply.

Integration of calibrated hydraulic network model, demand prediction and full (rapid-solving) optimisation algorithm.

Can be integrated with SCADA for automated implementation of network operation.

System integration delivered in partnership with the client’s preferred systems integration provider.