FREEFLOWi4.0 flexible, thermodynamic pump monitoring system

Our industry-leading FREEFLOWi4.0 thermodynamic pump monitoring system is easy to use, self-contained and wireless. It offers immense flexibility, highly suited to monitor pumps, blowers, fans and turbines at medium to large stations.

The system can be temporarily or permanently installed on-site, directly assessing actual operational performance, continuously gathering data and driving ongoing optimisation work.

Why use a thermodynamic pump monitoring system?

Pump system characteristics typically change with demand and station operation, particularly within larger pumping stations where absolute precision is necessary. Changes can be observed and controlled using a thermodynamic pump monitoring system over a set period.

Often hidden characteristics are discovered that can lead to major improvements in overall operating efficiency and asset lifecycle costs.

Make real-time pump optimisation a reality

Results can provide valuable data for real-time optimisation, and for planning capital expenditure and minimising whole-life costs. Monitoring can also reduce energy consumption, carbon emissions, hydraulic failure and premature wear.

How the FREEFLOWi4.0 works

Because a pump is usually part of a dynamic system, its contribution will vary with demand and system characteristics.

Our FREEFLOWi4.0 system can monitor hydraulic performance and pump efficiency. In conjunction with our operator interface software, the real-time effectiveness of each pump can be evaluated, and accurate data generated to make optimisation happen.

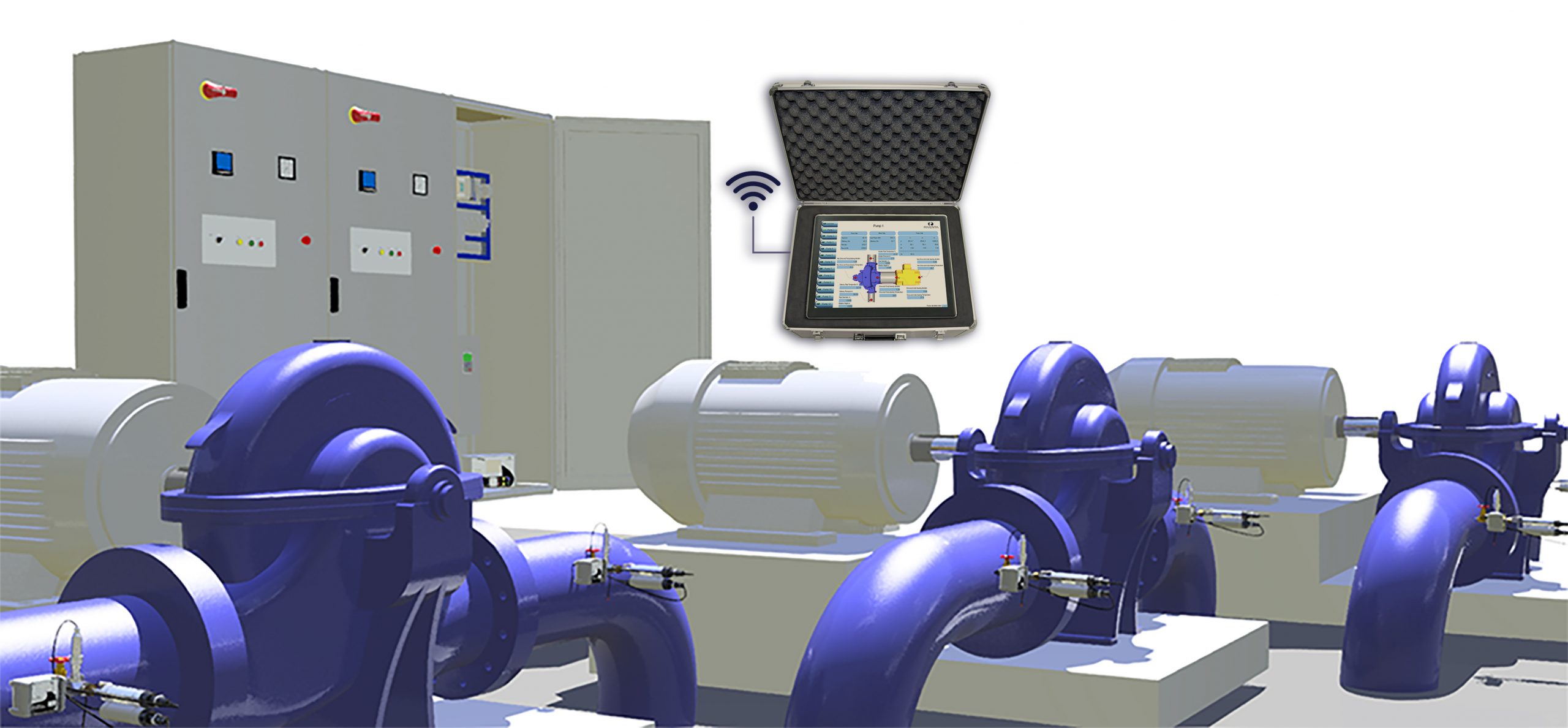

Above shows a render of our FREEFLOWi4.0 connected to a series of pumps and wirelessly feeding data to a nearby FREEFLOW HMI box.

COMMONLY MONITORED APPLICATIONS

For medium to large pumping stations with typical pump size of 50kW and above

SYSTEM COMPONENTS

One set of precision temperature transducers

One 10-bar suction pressure transducer

One 20-bar delivery pressure transducer

One power measurement system (LV/HV)

One touch screen local operator panel

Two insertion glands per pump

SYSTEM HIGHLIGHTS

Enables motor efficiency to be measured using our patented technology

Measures individual pump efficiency and flow rate

Supports planned maintenance programmes by tracking reduction in pump efficiency

Trends data to predict the most cost-effective time for pump replacement, refurbishment, coating or other remedial maintenance

Provides pump head, flow, efficiency, power and motor efficiency

Integrates with SCADA, standalone or web-access (security assured)Delivers the following real-time data, which are the building blocks of optimisation: pump efficiency (%), motor power (kW), flow rate (l/s) and pump head (m).The following measurements are taken: hydraulic measurement (differential temperature, suction pressure, discharge pressure), electrical power measurement (kW), asset performance information and motor efficiency measurement (%).Captures, processes and provide data to managers and operators via our interface software. Every minute of the day and night, enhanced information is made available from FREEFLOW to improve station efficiency and reduce operating costs.