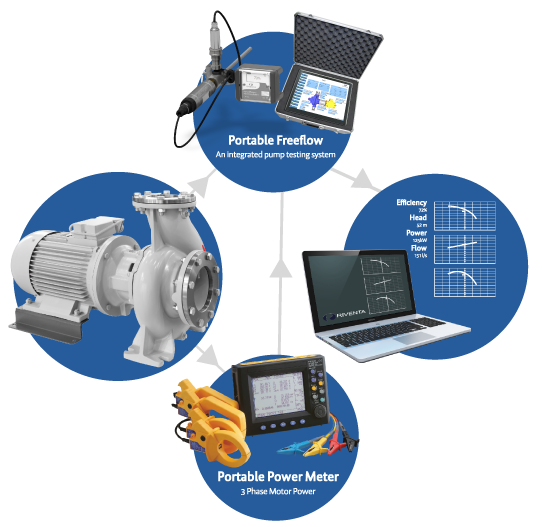

FREEFLOW portable thermodynamic pump testing system

Our industry leading FREEFLOW portable thermodynamic pump testing system is an easy to use, self-contained thermodynamic instrument. It is one in our range of pump testing systems designed to measure pump performance characteristics on industrial pumps.

Why use a thermodynamic pump testing system?

Using our thermodynamic method remains the most accurate and powerful means of testing a pump. The portable system makes this easy to do in-situ, without compromise to safety or disruption to operations.

By simply measuring temperature and pressure across the pump, our precision technology calculates the efficiency and head of the pump (to an impressive accuracy of up to 0.5%). Then, by measuring the power consumed by the motor, we can calculate flow rate.

How the FREEFLOW portable works

Where existing pipework fittings are installed, an experienced technician can complete a typical pump test in less than two hours. A range of test points are taken at different flow rates, across the operating range of the pump. This data is used to plot performance curves of the pump under test.

COMMONLY TESTED APPLICATIONS

Split Case Pumps

Blowers

Fans

Hydro Turbines

Vertical Turbines

Suitable for both low and high head applications

BASIC FEATURES

Real-time measurement quality indicators

Pump test wizard for test set-up guidance

Industry standard analysis software

Electrically isolated current transformers (to improve safety)

Thermodynamic measurements meet ISO 5198

SYSTEM HIGHLIGHTS

Easy to use, intuitive software

Easily understand pump test results in clearly presented formats

Readily interpret and evaluate the condition of a pump using easy to read performance curves

Make comparisons with manufacturers curves and previous tests (where data is available) in a matter of minutes